We lately had a conversation with LS Electric, initially component of the LG Team, started in 1974 as Lucky Packaging. In 2003, it divided from LG and entered into the LS Group, rebranding as LSIS. In 2020, LSIS embraced its existing name, LS Electric.

LS Electric concentrates on power devices, automation systems, and remedies for nuclear power plant, substations, and distribution networks. Their services likewise include power tools diagnostics and precautionary upkeep systems.

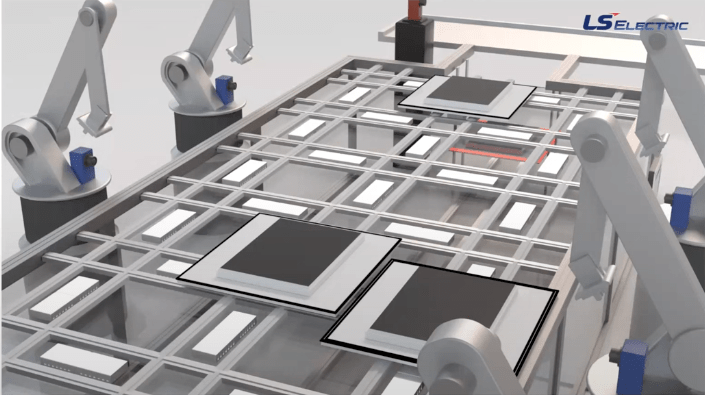

We explored their LS Smart Relocating Monitoring System (SMMS) in our discussions with LS Electric. This conveyor-belt replacement system utilizes a magnetic pressure as opposed to traditional belts to move objects along production lines.

The essential advantage of SMMS is that magnetic force is used directly to the item being moved– specifically, to palettes furnished with magnets– as opposed to relying upon a conveyor belt that relocates the entire line. Coils and sensors in the system induce magnetic forces to displace the schemes, allowing activity with much greater performance. This system allows schemes to relocate up and down, developing multi-level production lines where items can be lifted or lowered in between different paths.

Because the activity is contactless, the SMMS experiences less friction and contamination than standard conveyors. Without a moving belt, the danger of conveyor-related mishaps is considerably lowered. LS Electric highlights that in the united state alone, conveyor belts are responsible for around 9, 000 accidents each year, making safety and security one of SMMS’s most substantial advantages.

An additional clear human security advantage is decreasing dust, pollutants, and lubricating substances in the workspace, many thanks to getting rid of belt rubbing.

Along with enhanced safety and security, the lack of rubbing means a longer life expectancy for the system, though even more data is required to measure this in time.

Beyond equipment, SMMS provides a remarkable software application user interface. Users can customize production lines with a visual drag-and-drop device. Some coding can be produced via a ChatGPT-powered interface, with integrated confirmation to guarantee capability. The software runs in a web browser, permitting remote modifications making it easier for experts to take care of numerous websites or respond rapidly to concerns. Couple of commercial systems supply this user-friendly experience, signifying a trend towards extra accessible innovation in this market.

LS Electric keeps in mind that SMMS is energy-efficient, as it only moves the objects, not the whole production line. While this case makes sense in theory, we aspire to see even more data when it appears. LS Electric will certainly be showing its innovation at CES 2025

https://www.youtube.com/watch?v=ggvjYdJng 4 Y

Filed in Find out more concerning CES, CES 2025 and Korea.